Description:

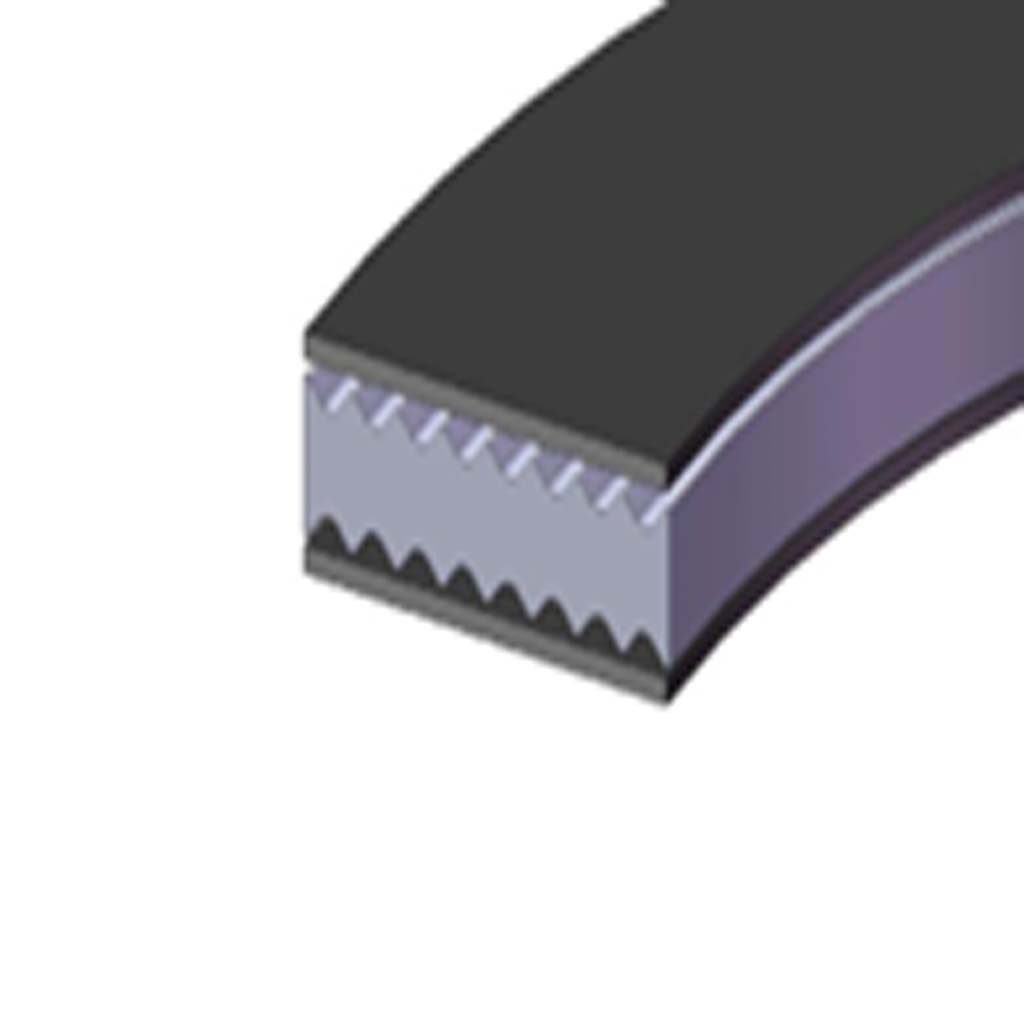

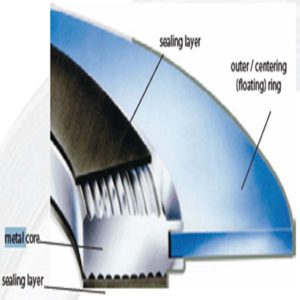

A Kammprofile gasket is manufactured by applying a sealing layer in non-metallic materials (such as graphite, PTFE-Teflon, ceramic fibers, non-asbestos, Mica, etc) or metallic materials (as aluminum or silver) on both sides of a metal core featuring concentric grooves of 1 mm Cam-Pitch. This sealing product, called also “grooved metal gasket” or “corrugated metal gasket”, is used for high-pressure and temperature oil & gas applications.

Kammprofile gaskets are used in many industrial, petrochemical, power generation and nuclear installations (to seal flanges, heat exchangers, superheaters and, other pressure equipment) and are preferred to Spiral Wound Gaskets for processes with constant high pressure/temperatures requiring strong bolt-loads and remarkable flanged joints’ resistance.

A Kammprofile gasket offers several benefits, due to its wide sealing area and construction:

· Manufactured as per ASME/BS standards.

· Meeting DOW & SHELL (MESC SPE) requirements.

· Wide range of seating stresses under which seal conventional gasket materials.

· Can be used when there is insufficient bolt load to seal conventional gasket materials.

· Easy to handle and fit.

· Suitable for a wide range of operating conditions.

· Soft facing layer prevents damage to the mating flange.

· Sealing is not sensitive to uneven bolt loading conditions.

· Can be refurbished with a new facing layer and reused.d

FACING MATERIAL | MAXIMUM TEMPERATURE |

Graphite | 550°C |

PTFE | 260°C |

Mica | 1000°C |

CORE MATERIAL | CORE MATERIAL |

316L Stainless Steel | 800°C |

304 Stainless Steel | 650°C |

347 Stainless Steel | 870°C |

321 Stainless Steel | 870°C |

Monel 400 | 800°C |

Copper Nickle | 800°C |

Inconel 600 | 1000°C |

Inconel 625 | 1000°C |

Inconel 825 | 600°C |

Alloy 20 | 600°C |

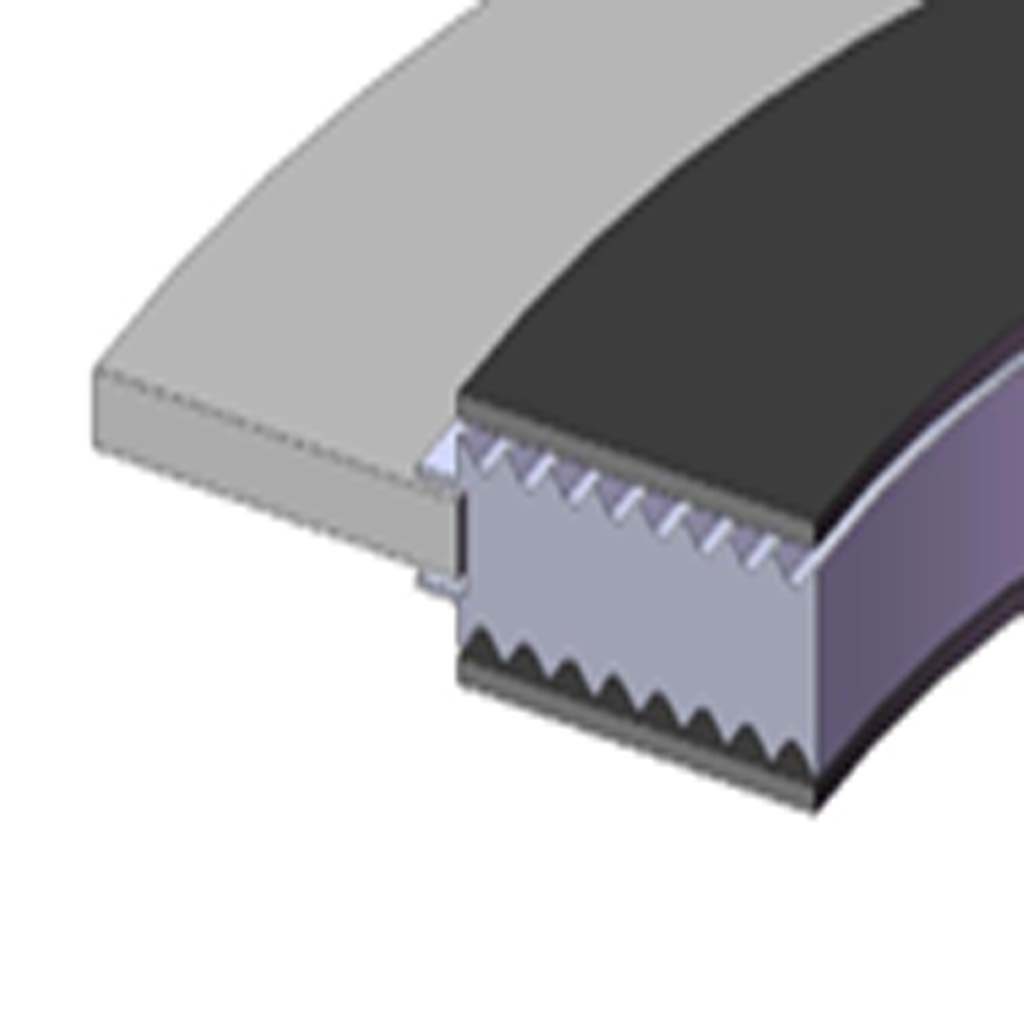

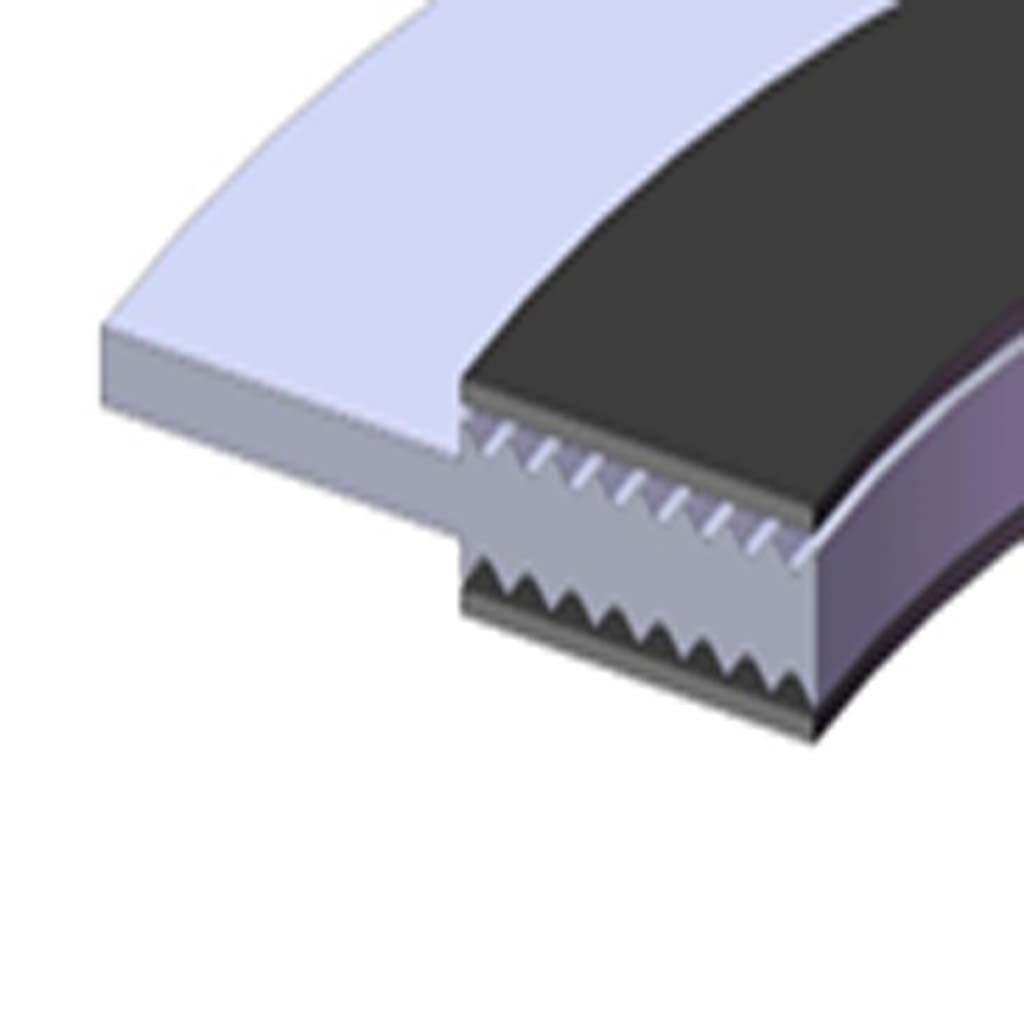

Lateral profiled joint with guide ring for raised and flat face applications.