Description:

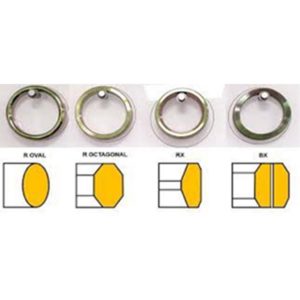

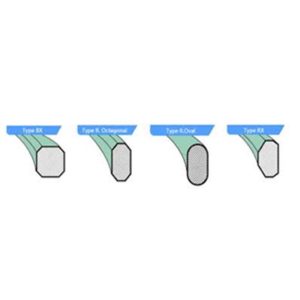

Ring Joint Gaskets (RTJ) are metallic sealing rings that fit into ring grooves and are ideal for high pressure and high temperature applications. They are commonly utilized in valves and pipes in the petrochemical and oil sectors. The choice of material may be determined to suit higher temperatures and aggressive media. They comply with ASME B16.20 standards.

To guarantee appropriate deformation of the gasket without harming the flange face, the RTJ gasket material is chosen based on the chemical compatibility with the media and the flange’s hardness.

|

TYPE |

NOMINAL PIPE SIZE |

CLASS RATINGS |

|

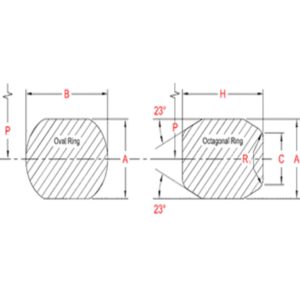

Type R Oval and Octagonal |

1/2″ to 24″ 26″ to 36″ 1 ½” to 20” |

150 to 2500 ASME B16.20 300 to 900 ASME B16.20 Series A API 6A |

TYPE RX |

1 1/2″ to 24″ 26″ to 36″ 1 ½ ” to 20″ |

720 to 5000 ASME B16.20 300 to 900 ASME B16.20 API 6A |

|

Type BX |

1 11/16″ to 21 1/4″ |

5000 to 20000 ASME B16.20 |

|

MATERIAL |

BRINELL HARDNESS |

TEMPERATURE LIMITATION |

IDENTIFICATION |

|

Soft Iron |

90 |

-60 to 500 °C |

D |

|

Low Carbon Steel |

120 |

-40 to 500 °C |

S |

|

4-6% Cr ½% Mo |

130 |

-250 to 500 °C |

F5 |

|

304 |

160 |

-250 to 550 °C |

S304 |

|

316 |

160 |

-110 to 550 °C |

S316 |

|

321 |

160 |

-250 to 550 °C |

S321 |

|

347 |

160 |

-250 to 550 °C |

S347 |

|

410 |

170 |

-20 to 500 °C |

S410 |

|

Inconel 625 |

– |

450 °C |

625 |

|

Incoloy 825 |

– |

450 °C |

825 |

|

Hastelloy C-276 |

– |

450 °C |

C-276 |

|

Titanium |

– |

450 °C |

TI |