Description:

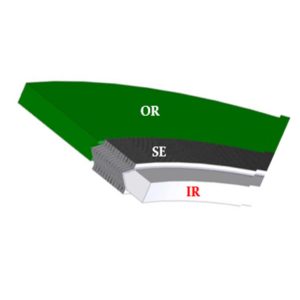

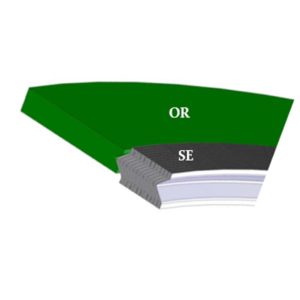

Spiral wound gaskets can be manufactured in a variety of styles, sizes, and densities where it’s a combination of a filler material made from graphite, PTFE, or mica and a profiled metal are available, which enables the gasket to meet the requirements of varied operating conditions. Based on metal selection and filler, it can be used against virtually any corrosive medium.

|

FILLER MATERIAL |

MAXIMUM TEMPERATURE |

ASME B16.20 COLOR CODING |

|

Graphite |

550°C |

Grey Stripe |

|

PTFE |

260°C |

White Stripe |

|

Mica |

1000°C |

Light Green Stripe |

|

WINDING MATERIAL |

MAXIMUM TEMPERATURE | ASME B16.20 COLOR CODING |

|

304L Stainless Steel |

650°C |

Yellow |

|

316L Stainless Steel |

800°C |

Green |

|

347 Stainless Steel |

870°C |

Blue |

|

321 Stainless Steel |

870°C |

Turquoise |

|

Monel 400 |

800°C |

Orange |

|

Inconel 600 |

1000°C |

Gold |

|

Inconel 625 |

1000°C |

Gold |

|

Inconel 825 |

600°C |

N/A |

|

Super Duplex |

600°C |

N/A |

| Alloy 20 | 600°C |

N/A |

SPIRAL

WOUND GASKETS -ASME COLOR CODES

METALLIC WINDING | ABBREVIATED | COLOR CODE |

Carbon | CRS | Silver |

304 | 304 | Yellow |

304 | 304 L | No color |

309 | 309 | No color |

316 | 316 L | Green |

347 | 347 | Blue |

321 | 321 | Turquoise |

Monel | MON | Orange |

Nickel | NI | Red |

Titanium | TI | Purple |

Hastelloy | HAST B | Brown |

Hastelloy | HAST C | Beige |

FILLER

MATERIAL – RIM STRIPE COLOR

| POLYTETRAFLUOROETHYLEN | PTFE | WHITE STRIPS |

Flexible graphite | F.G. | Gray stripe |

Ceramic | CER | Light green |

Mica Paper |

| Pink |